1.Clear Window

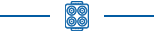

2.Tactile & Non-Tactile

3.Silver Flex Circuit

3.Embedded LED’s, Resistors & sensors

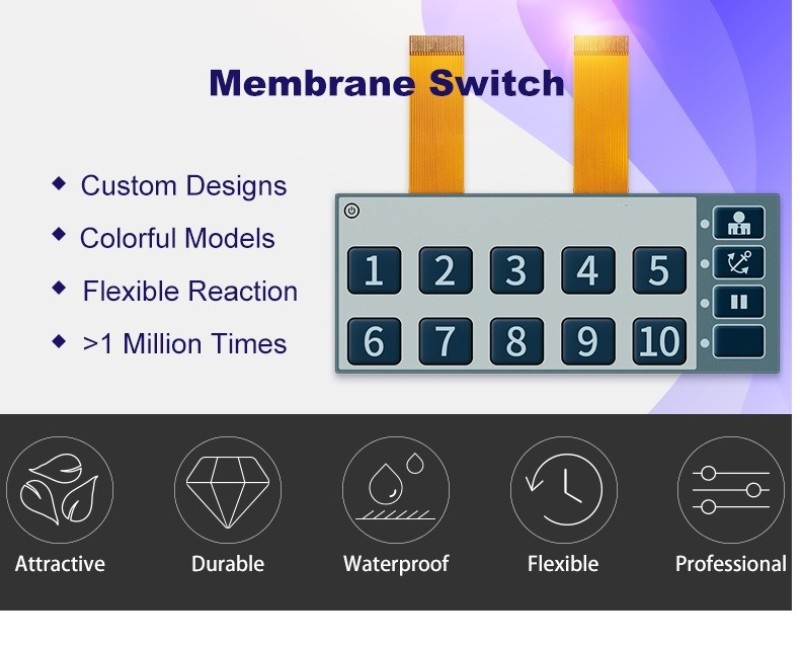

4.Able to make to customer’s waterproof requirement & UV protection design

5.Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light.

6.ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static

| Main Technical Parameters | |

| (1) Electrical Properties | |

| 1.Operating voltage: | ≤ 50VDC |

| 2.Working current: | ≤ 100mA |

| 3.Contact resistance: | 0.5 ~ 5Ω |

| 4.Insulation resistance: | ≥ 100MΩ (100VDC) |

| 5.Substrate voltage: | 2kDVC |

| 6.Spring time: | ≤ 6ms |

| 7.Loop resistance: | 30Ω |

| 8.Insulation ink voltage: | 100VDC |

| (2) Mechanical Properties | |

| 1. reliability, service life: | > 1 million times |

| 2. closed displacement: |

0.1 ~ 0.4mm (no touch-type) 0.4 ~ 1.0mm |

| 3. health standard for power: | 280g Power |

| 4. silver migration: |

In 55 ℃, humidity 90%, 56 hours later, the second-line between the 10MΩ/50VDC |

| 5. silver online no oxidation, no impurities | |

| 6.silver width |

≥ 0.3mm, the smallest interval of 0.3mm, line edges <1 / 3, the line gap of <1 / 4 width |

| 7.pin spacing standard | 2.54mm |

| 8.lead anti-curvature, with d |

10mm steel rod line pressure roller 80 constantly. |

| (3) environmental performance | |

| 1. operating temperature: | -40 ℃ ~ +80 ℃ |

| 2. storage temperature: | -40 ℃ ~ +85 ℃ temperature of 95% ± 5% |

| 3. atmospheric pressure: | 86 ~ 106kDa |

| (4) print index | |

| 1. print size deviation |

± 0.15mm, clear code looks bad ≤ 0.1mm edges |

| 2. chromatic deviation |

± 0.11mm/100mm, insulated cover all the Silver Line Ink |

| 3. no ink dispersion, writing non-defective | |

| 4. chromatic aberration is not more than two | |

| 5. may have creases, paint stripping | |

|

6. transparent windows transparent clean, uniform color, not a scratch, and impurity |

|

|

Overlay Material

|

PET, PC,Silicone, Metal

|

|

Artwork Format

|

CorelDraw, Adobe Illustrator AI, AutoCAD, CDR

|

|

Color

|

Pantone and RALcolor matching system

|

|

Button

|

Embossed/Flat/Metal/Silicone/Rubber

|

|

Keys Options

|

Tactile: metal domes or poly domes

|

|

Non-tactile: flat button, printed silver spot on the circuit

|

|

|

Connector Tail

|

Zero insertion force(ZIF) with 0.5MM ,1.0MM,1.25MM pitch

|

|

Female connector with 2.54MM pitch

|

|

|

Circuitry option

|

Silver printed conductive inks, FPC, PCB

|

|

Printing

|

Screen printing, Semi-Auto matic printing, Automatic Printing

|

|

Window

|

Clear or transparent, translucent, red/black/white/green etc transparent window

|

|

Surface

|

Glossy surface or matte surface

|

|

Rear Adhesive

|

3M467,3M468, 3M9080, 3M9495, 3M7959,3M9471, 3M300VHB, etc...

|

|

Certificate

|

ISO9001、RoHS、CE、SGS,ISO13485,TS16949

|

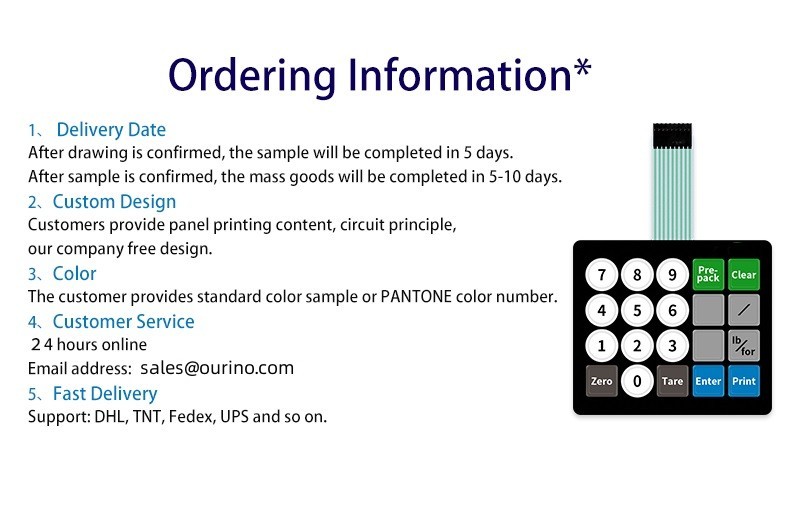

September 18, 2020

September 18, 2020 February 08, 2023

February 08, 2023 February 22, 2017

February 22, 2017

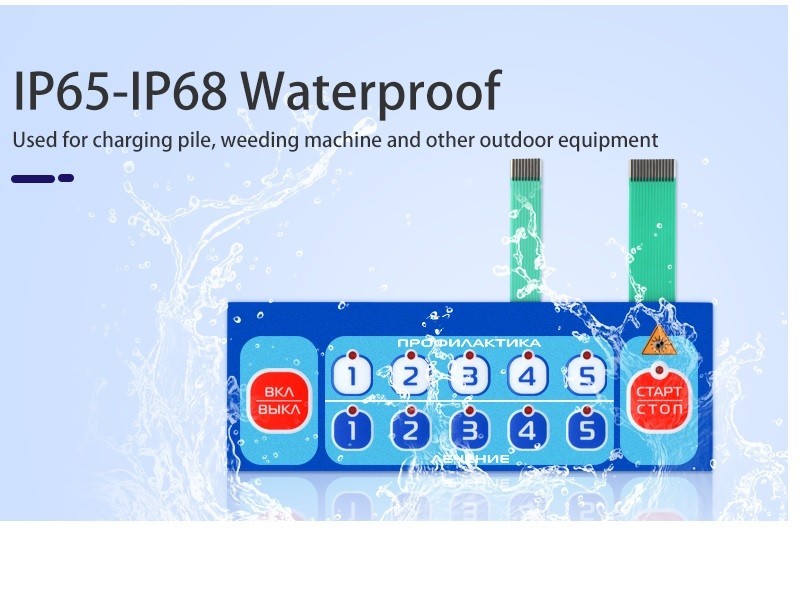

1.Tactile & Non-Tactile 2. Silver Flex Circuit 3. Embedded LED’s, Resistors & sensors 4. waterproof requirement(IP65-IP68) & UV protection design 5. Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light. 6. ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static

Learn More

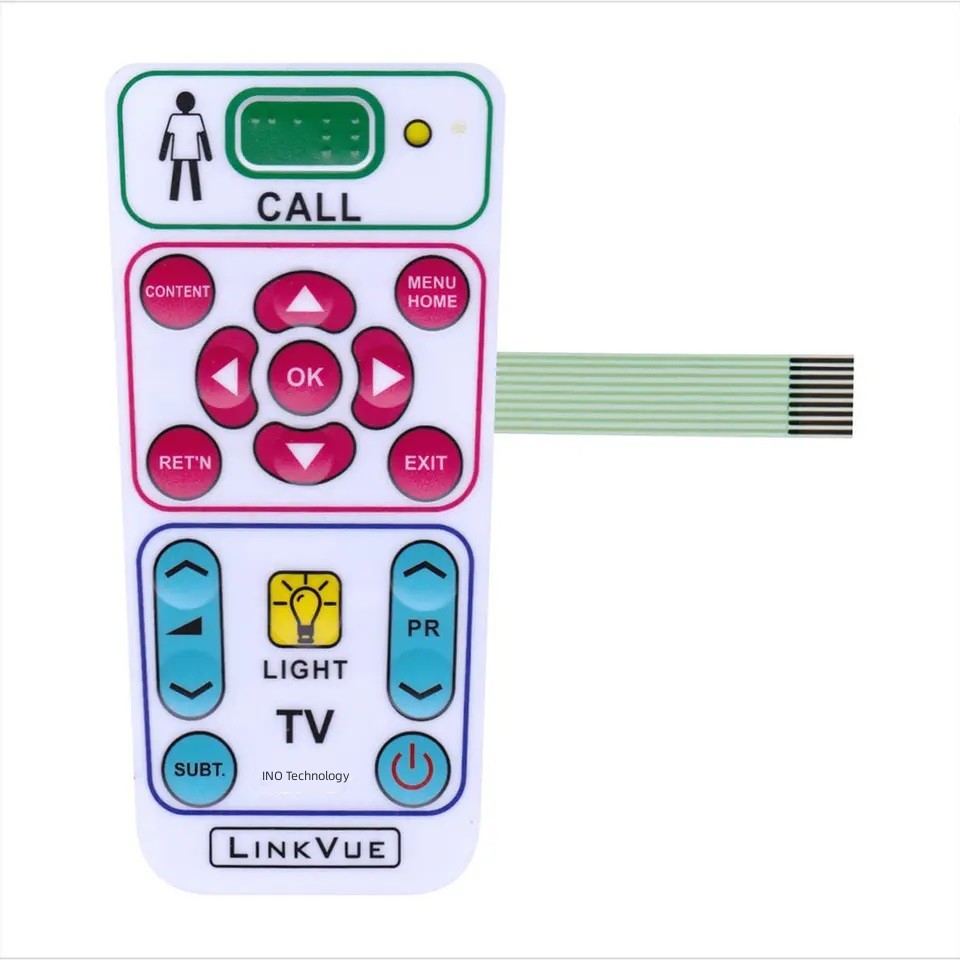

1. OEM & ODM Service 2. Silver Flex Circuit 3. Embedded LED’s, Resistors & sensors 4. Able to make to customer’s waterproof requirement & UV protection design 5. Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light. 6. ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static 7. Tactile & Non-Tactile

Learn More

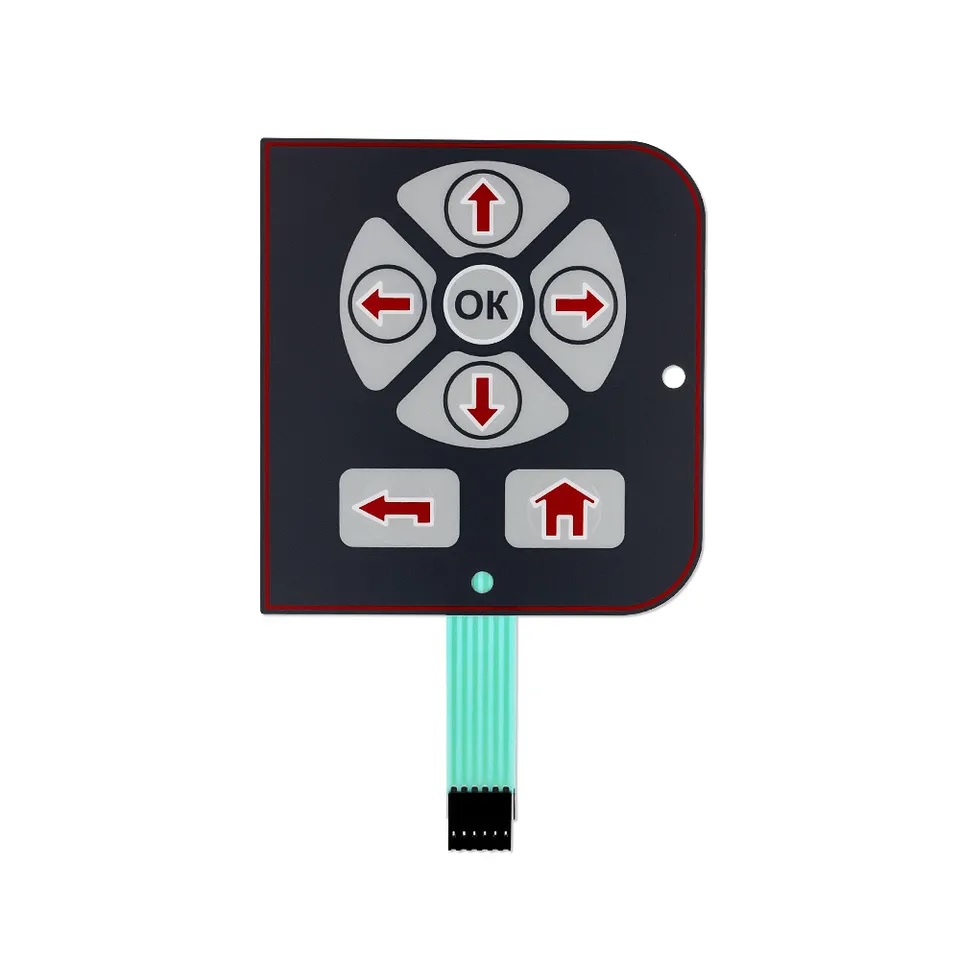

1. Silver Flex Circuit 2. Tactile & Non-Tactile 3. Embedded LED’s, Resistors & sensors 4. Waterproof requirement & UV protection design, which is used for charging pile, weeding machine and outdoor equipment 5. Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light. 6. ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static

Learn More

1.ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static 2. Silver Flex Circuit 3. Embedded LED’s, Resistors & sensors 4. Able to make to customer’s waterproof requirement & UV protection design 5. Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light. 6. Tactile & Non-Tactile

Learn More

1.Waterproof IP 65-IP68 2.Tactile & Non-Tactile 3. Silver Flex Circuit 4. Embedded LED’s, Resistors & sensors 5. UV protection design 6. Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light. 7. ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film antia-static

Learn More

1.Silver Flex Circuit 2. Embedded LED’s, Resistors & sensors 3. Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light 4. Waterproof requirement & UV protection design 5. Tactile & Non-Tactile 6. ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static

Learn More

1.Tactile & Non-Tactile 2. Shielding design: EMI, RFI and ESD shielding (Silver shielding, Carbon shielding, ITO shielding) 3. Embedded LED’s, Resistors & sensors 4. Able to make to customer’s waterproof requirement & UV protection design 5. Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light. 6. ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static

Learn More

1.Clear Window 2.Tactile & Non-Tactile 3.Silver Flex Circuit 3.Embedded LED’s, Resistors & sensors 4.Able to make to customer’s waterproof requirement & UV protection design 5.Fiber Optic & Electroluminescent Backlighting,EL back light, LED back light effect, Light Guild Film (LGF or LGP) back light, Fiber Optic Back light. 6.ESD Anti-Static Design: using Aluminum Foil, Printing AG or C plasma , ITO Film anti-static

Learn More Room 404,No.189,LianYue Road, Siming District,Xiamen, China 361006

Room 404,No.189,LianYue Road, Siming District,Xiamen, China 361006 +86-592-5539868

+86-592-5539868 [email protected]

[email protected]