|

Item

|

Fire Resistant Nylon Plastic Snap in End Plug/End Cap

|

|

Material

|

ABS, PC/ABS, PP, PC, POM(Acetal/Delrin), Nylon 6, Nylon 6/6, PA 12, HDPE, LDPE, PS(HIPS), PMMA(Acrylic), SAN/AS, ASA, PVC, UPVC, TPE, TPR, PU, TPU, PET, PEI(Ultem), PSU, PPSU, PPE/PS, PTFE(Teflon), GPPS, PPS, PPO, PES, CA, etc.

|

|

Performance

|

UV Resistance, Heat Resistance, Fire Resistance, Good Flexibility, etc.

|

|

Certificate

|

IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB

|

|

Drawing Format

|

.stp / .step / .igs /.stl /.dwg / .pdf. etc.

|

|

Color

|

Almost all PMS colors available.

|

|

Parameters

|

Inch, centimeter, millimeter, etc.

|

|

Function

|

Industrial parts /daily supply / Medical grade supply, etc.

|

|

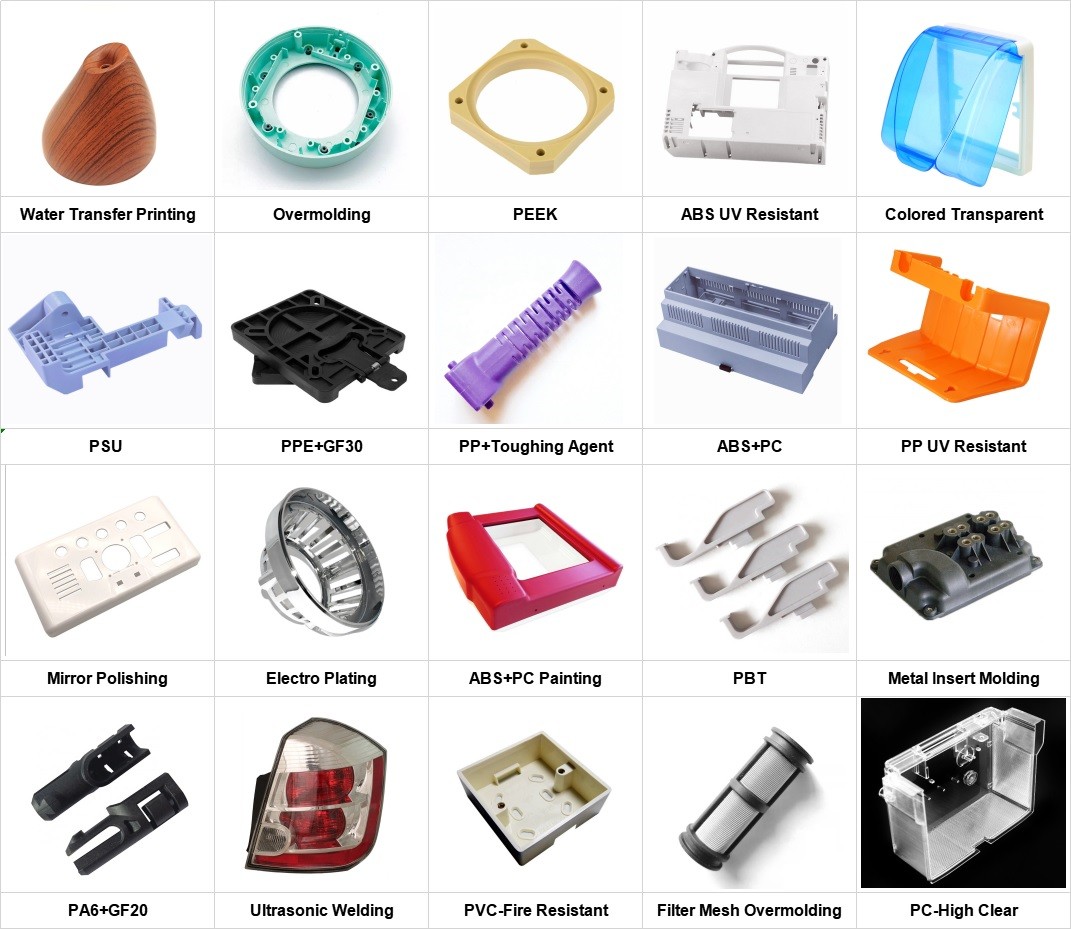

Surface Treatment

|

Matte, Common polishing, Mirror polishing, Texture, Plating, Power Coating (Painting), Laser Engraving, Brushing, Marbling, Printing etc.

|

|

Mold Material

|

S136H, 718H, NAK80, P20, H13, etc.

|

|

Mold Precision

|

If no special request, apply to SJ/T10628-1995 standards, class 3.

|

|

Mold Life-cycle

|

100,000-500,000 shots.

|

|

Packing

|

Pack in bulk / poly bag / bubble bag / color box.

|

|

Sample

|

Available. One cavity sample mold or 3D printing.

|

Plastic injection molding is the preferred process for manufacturing plastic parts, as it is ideal for producing high volumes of low-cost plastic parts with high tolerance precision, repeatability and little to no finishing required.

You can refer to the following process, communicate with our customer service, we will give you the best quality service and the most satisfactory price and products.

STEP 1 Define & Design

First, we get to know you and how you plan to use your part. Our team of expert in-house engineers will then create technical drawings. If you already have spec drawings, we can use them.

STEP 2 Prototype & Build

Once you’re satisfied, we schedule your part for production — and keep you updated with expected delivery dates.

STEP 3 Ship you the perfect part

Enjoy plastic parts that slide easily into your production schedule.

There are some plastic parts for reference:

September 18, 2020

September 18, 2020 February 08, 2023

February 08, 2023 February 22, 2017

February 22, 2017

The advantages of using automotive plastic parts are many and varied. One benefit is that plastic can be manipulated and formed into a myriad of shapes and sizes. From molds for the interior of the car to core components on the outside, you can rely on different types of plastic for a variety of vehicle parts.

Learn More

Our complete design and manufacturing process includes part modeling and mold design, prototyping, tool sourcing, production planning, sample verification, process control, decorating, secondary processing, and packaging. The advantages of using automotive plastic parts are many and varied. One benefit is that plastic can be manipulated and formed into a myriad of shapes and sizes. From molds for the interior of the car to core components on the outside, you can rely on different types of plastic for a variety of vehicle parts.

Learn More

Our complete design and manufacturing process includes part modeling and mold design, prototyping, tool sourcing, production planning, sample verification, process control, decorating, secondary processing, and packaging. The advantages of using automotive plastic parts are many and varied. One benefit is that plastic can be manipulated and formed into a myriad of shapes and sizes. From molds for the interior of the car to core components on the outside, you can rely on different types of plastic for a variety of vehicle parts.

Learn More

OEM&ODM is welcomed Rapid Prototyping On-demond production services IATF16949 ISO9001 ISO14000 Certificate Professional DFM Report before Mould Making Capability for Plastic Injection Molding is up to 1500m

Learn More

Rapid Prototyping OEM&ODM is welcomed On-demond production services IATF16949 ISO9001 ISO14000 Certificate Professional DFM Report before Mould Making Capability for Plastic Injection Molding is up to 1500m

Learn More

On-demond production services Rapid Prototyping,3D printing Model IATF16949 ISO9001 ISO14000 Certificate Professional DFM Report before Mould Making Capability for Plastic Injection Molding is up to 1500m

Learn More

Double-Shot Molding On-demond production services IATF16949 ISO9001 ISO14000 Certificate Professional DFM Report before Mould Making Capability for Plastic Injection Molding is up to 1500m

Learn More

3D Rapid Printing Model On-demond production services IATF16949 ISO9001 ISO14000 Certificate Professional DFM Report before Mould Making Capability for Plastic Injection Molding is up to 1500m

Learn More Room 404,No.189,LianYue Road, Siming District,Xiamen, China 361006

Room 404,No.189,LianYue Road, Siming District,Xiamen, China 361006 +86-592-5539868

+86-592-5539868 [email protected]

[email protected]